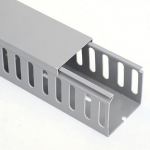

Polyethylene corrugated pipe (PE corrugated pipe) is a flexible pipe made of high-density polyethylene (HDPE) as the main raw material through extrusion molding and corrugation mold shaping. The product has a double-layer structure: the outer layer is an annular corrugated structure, and the inner layer is a smooth structure. It has both high strength and excellent flexibility and is widely used in cable protection, drainage and sewage, communications, municipal engineering and other fields.

2. Product structure characteristics

Excellent material: Made of high-quality high-density polyethylene, environmentally friendly, non-toxic and corrosion-resistant.

Reasonable structure: The outer wall is a corrugated reinforced structure with strong compressive resistance; the inner wall is smooth and has a low friction coefficient, which is convenient for threading or drainage.

Convenient connection: It adopts socket, hot melt, rubber ring connection and other methods, which is simple and fast to construct and has good sealing performance.

Strong flexibility: It can be bent, adapt to terrain changes, and is suitable for trenchless construction.

High durability: It is resistant to aging, UV and chemical corrosion, and its service life can reach more than 50 years.

3. Product classification

Single-wall corrugated pipe

Both the inside and outside are corrugated, suitable for weak-current cable threading protection, small drainage and other fields.

Double-wall corrugated pipe

The outer wall corrugation is enhanced, the inner wall is smooth, and it is widely used in underground drainage and sewage systems.

Steel-reinforced polyethylene corrugated pipe (HDPE-SR)

The steel-reinforced layer is sandwiched in the middle, suitable for high-strength municipal drainage and sewage pipes.

4. Main application areas

Municipal drainage and sewage systems

Communication cables and optical cables protection

Electric power line pipelines

Highway and railway engineering drainage systems

Farmland water conservancy and underground irrigation projects

5. Specifications (some examples)

Nominal outer diameter (mm) Ring stiffness grade (kN/㎡) Length (m/root)

110 ≥4 (SN4) 6/9

160 ≥8 (SN8) 6/9

200 ≥8 (SN8) 6/9

315 ≥8 (SN8) 6/9

Customizable Customized on demand Customized on demand

6. Summary of product advantages

Light weight, easy transportation and installation

Compression and shock resistance, long service life

Corrosion resistance, wear resistance, environmental protection and pollution-free

Can replace traditional materials such as cement pipes, cast iron pipes, ceramic pipes, etc.

评价

目前还没有评价